Proper storing of engineering parts is significantly important; not only does it maintain quality, but it also ensures smooth running operations. Be it small bolts or bigger and complicated parts, an organized storage system is what keeps unnecessary downtime and expensive repairs at bay. Place fragile electrical components in anti-static containers, store the heavy parts in categories of size, and be prepared to be astonished at the difference it makes. Proper storage cleans up that space, gives room to work, and also prolongs the life of your parts, keeping projects on course.

Choosing the Right Storage Environment

When storing engineering parts, the right environment plays a key role in maintaining their integrity. Factors such as temperature, humidity, and space requirements can affect parts differently.

Here are some considerations for creating an optimal storage environment:

- Temperature control: Store temperature-sensitive parts in climate-controlled areas to avoid warping or material degradation.

- Humidity regulation: High humidity can lead to rust or corrosion, so ensure your space is dry, especially for metal components.

- Adequate ventilation: Proper airflow can prevent the buildup of dust and moisture, which could damage sensitive parts.

- Space allocation: Allocate enough space to avoid stacking or crowding, which can lead to breakage.

- Security: Ensure that expensive or rare parts are stored in secure, lockable spaces.

An expert suggests that proper temperature and humidity control are critical in preventing long-term damage to engineering parts, saving you from costly replacements down the line.

Note: Did you know? Storing parts in the wrong conditions can reduce their lifespan by up to 30%, leading to more frequent replacements.

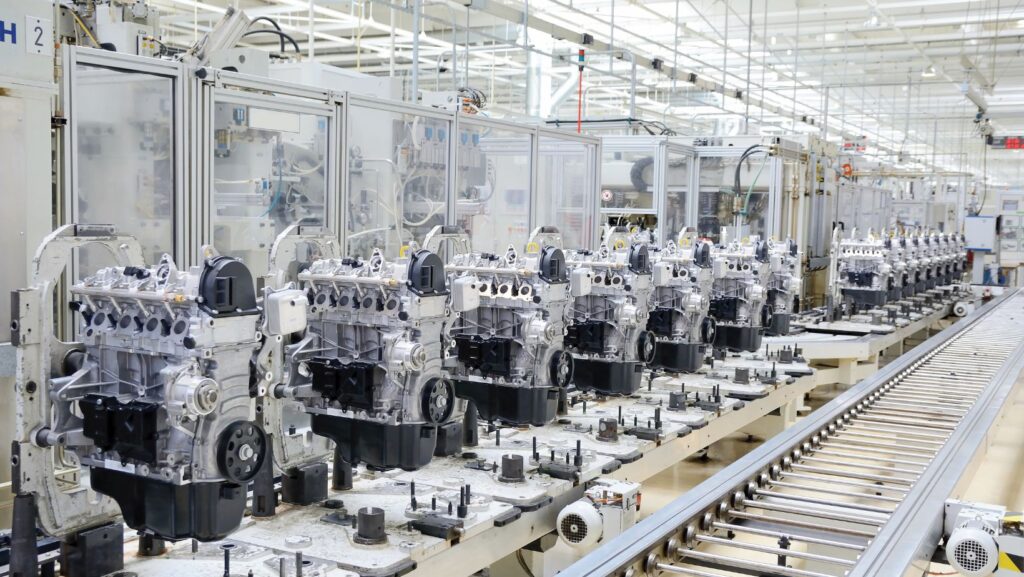

Organizing Parts by Size and Category

It is efficient in organizing engineering parts, mainly when you were dealing with items of different sizes and purposes. It saves time when all the small and big parts put together in their respective groups. It further avoids the potential damage to components due to piling or mixing them up. Small parts like screws and bolts may be set aside separately from larger, more sensitive pieces for convenience and not to lose them. Tailored Iowa storage solutions by NSA Storage offer customizable options for the easy implementation of such organizational strategies. Proper organization presents the ease of finding what you need in less time, hence making your workflow efficient and at minimal delay. You ensure that parts are logically separated and containers are used to ensure that your inventory is well managed and ready for use immediately. This way of organization also avoids some very costly mistakes, such as the duplication of orders or losses of crucial things.

Using Specialized Storage Containers

Engineering parts need to be stored in appropriate containers, not only for their safety and being kept in order but also for preventing them from damage. Be it fragile electronic components or massive machinery parts, the right storage solution can extend their useful life.

Following are three different types of specialized containers that find good use in the storage of engineering parts:

- Anti-static containers: These are ideal for storing sensitive electronic components, preventing static electricity from causing damage.

- Moisture-proof containers: For metal parts that are prone to rust, moisture-proof containers help keep humidity levels low, protecting them from corrosion.

- Heavy-duty bins: For larger and heavier parts, durable, heavy-duty bins provide extra support, ensuring that parts don’t bend, break, or cause injury during handling.

Research:

According to a study in the Journal of Industrial Materials Management, with the help of specific storage containers, it has been observed that the damage rate of parts decreases by 25%, which in turn reduces the number of replacements and repairs. The study emphasized that the type of container must match the particular part it stores, as an industrial part can have crucial operational delays even when minor damage happens.

The right containers mean you keep your engineering parts in order and protect them from the elements of weather that may lead to damage. You minimize replacement risks, which tend to cost more, while your parts will be ready to work whenever required. Such little investments in storage solutions sometimes make a big difference in terms of efficiency and safety in your workplace.

Labeling and Inventory Management

The engineering parts are stored in the warehouse, and good labeling and inventory are the major concerns. Poor labeling makes it very time-consuming to locate a certain part, hence causing unnecessary delays in projects. A well-organized labeling system involving part numbers, categories, and quantities facilitates tracing and fetching the parts in no time. This, along with an inventory management tool, will let you know what’s in stock at all times and avoid over-ordering or running out of important components. Updating the inventory list from time to time and arranging the parts by using clear labels will minimize mistakes and improve the workflow.

One expert in engineering storage said, “Inventory accuracy is the most important, as an efficient inventory has engineers finding parts instantly, and this keeps production or repair work right on schedule.” Consistent checks among inventories and labeled goods streamline processes while preventing costly delays.

Maintaining Cleanliness and Safety

Cleaning and safety within your engineering parts storage are some of the important factors that can make your component last longer and work effectively. By cleaning regularly, it means routine wiping of the surfaces to check on dust or debris accumulation that maybe causes potential contamination or damage to sensitive parts. Safe storage stepped up with a minimal percentage of accidents or injuries.

For example, keeping heavier items on lower levels and keeping places well-ventilated maintain a safe environment. Delicate components, sensors, or electronic parts should be stored in areas representative of the technology used to help keep the parts in smart homes protected from environmental elements: humidity or temperature fluctuations.

Stat Box:

According to studies, scheduled cleaning and maintenance performed in storage areas can reduce the damage that parts may incur by up to 35%, thus extending their lives or efficiency.

Cleaning and securing your storage not only protects your investment, but it also promotes workplace efficiency by reducing potential hazards. You ensure an orderly and safe storage facility once you make safety precautions a part of your routine.

Ensuring Longevity of Engineering Parts

Any effective storage solution will go a long way in preserving your engineering parts and ensuring their longevity. A well-organized system prevents damage, loss, or wear over time. You can extend the life of your components by selecting appropriate containers for storage, maintaining conducive environmental conditions, and keeping parts labeled and categorized. You may also monitor inventory regularly and observe cleanliness to safeguard your parts against degradation. These steps ensure that if parts are required, they are in the best condition and ready for immediate use. Proper storing not only minimizes part replacement costs but also aids in building an efficient and productive workspace. Finally, investing in the right storage strategy keeps the engineering parts serving longer and the operations running smoothly.