Monitoring and controlling operations without physical contact has become critical in today’s quickly changing industrial scene. Industries are increasingly depending on automation technology due to the need for greater accuracy, safety, and efficiency. Non-contact industrial sensors, advanced instruments that measure an object’s or material’s physical characteristics without requiring direct physical contact, are central to this revolution.

In many different industrial industries, non-contact sensors have become essential equipment. Using them has many benefits, such as increased safety, as there is no chance of direct touch or other potential risks. They greatly improve efficiency by facilitating quicker reaction times, greater accuracy, and less downtime. Additionally, by decreasing equipment wear and tear and the need for regular repairs, non-contact sensors help to minimize maintenance expenses. Most significantly, they guarantee accurate and consistent measurements throughout manufacturing, improving the final product’s quality.

A prime example of this technology is the Pepperl+Fuchs NBB20-U1-UU non-contact inductive sensor. This cutting-edge device utilizes electromagnetic fields to detect the presence and proximity of metallic objects, offering high sensitivity and exceptional reliability in demanding industrial environments.

This article will delve into the fundamental principles underlying non-contact industrial sensors, exploring their diverse types, examining their wide-ranging applications across various industries, and highlighting their significant benefits in modern manufacturing.

Working Principles of Non-Contact Sensors

Without making physical touch, non-contact sensors communicate with the material or object being measured. Usually, energy in the form of electromagnetic fields, light, sound waves, or infrared radiation is exchanged during this interaction.

- Electromagnetic Induction: This principle underlies the operation of inductive sensors, where a changing magnetic field induces a current in a target object. By measuring the strength of this induced current, the sensor can determine the proximity or presence of the object.

- Capacitance: Capacitive sensors utilize changes in capacitance to detect the presence or proximity of objects. Capacitance is the ability of a system to store an electrical charge. When an object enters the sensor’s field, it alters the capacitance, which is then measured by the sensor’s electronics.

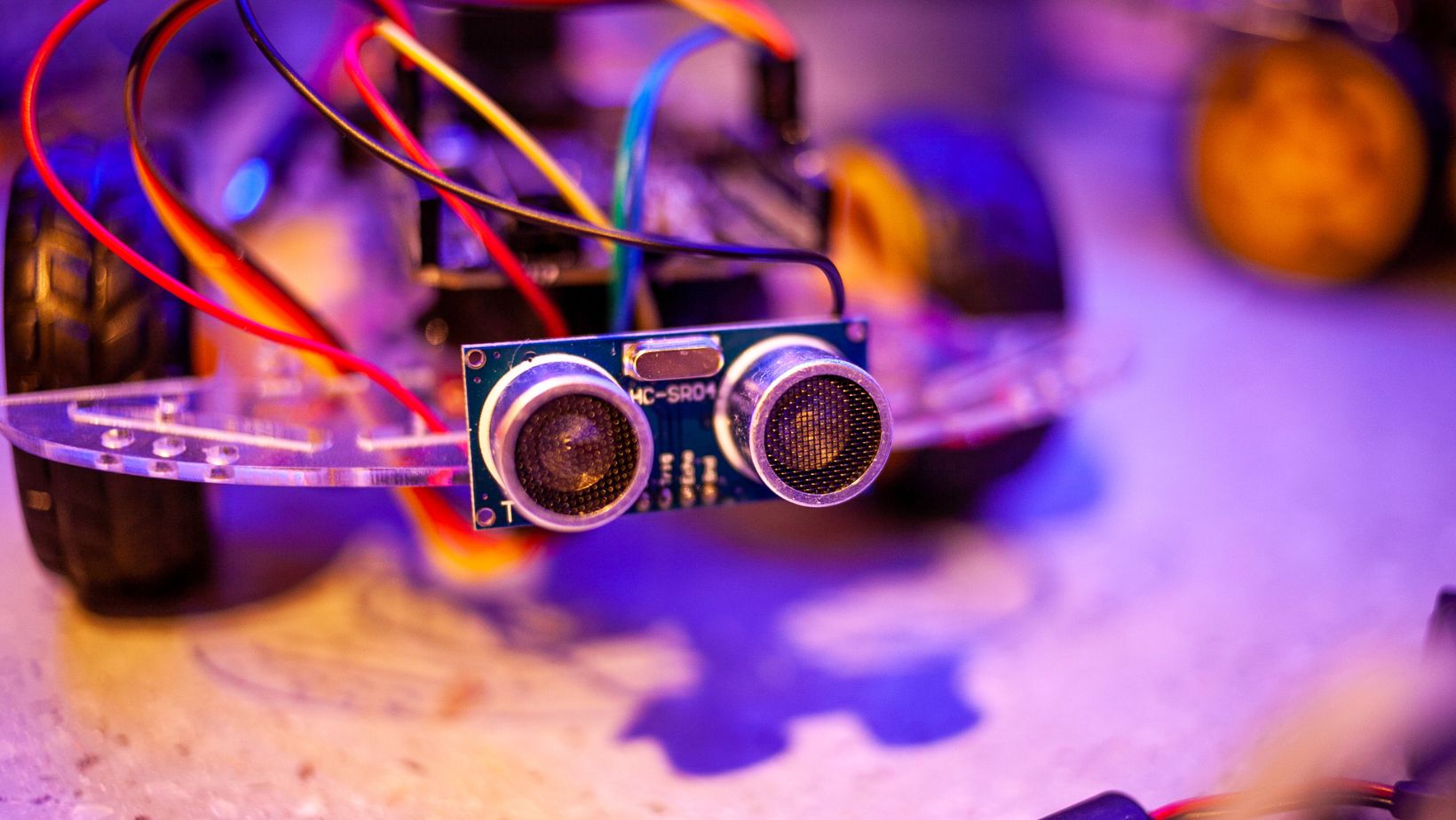

- Ultrasonic Waves: High-frequency sound waves are emitted by ultrasonic sensors, which then determine how long it takes for an item to reflect them. By examining the flight period, the sensor may calculate the distance to the item.

- Infrared Radiation: Infrared sensors detect infrared radiation emitted or reflected by objects. By analyzing the intensity and wavelength of this radiation, the sensor can measure temperature, detect motion, or determine the presence of objects.

- Photoelectric Effects: Photoelectric sensors utilize the photoelectric effect, where light striking a surface causes the emission of electrons. By measuring the current generated by these emitted electrons, the sensor can detect the presence or absence of an object interrupting a light beam.

These basic ideas are the foundation for various non-contact sensors in different industrial settings, allowing for accurate measurement and control without physical contact.

Types of Non-Contact Sensors

Non-contact sensors can be broadly categorized based on their underlying working principles:

- Inductive Sensors: These sensors operate on the principle of electromagnetic induction. They are primarily used for detecting the presence and proximity of metallic objects. When a metallic object enters the sensor’s magnetic field, it induces eddy currents within the object, which are then detected by the sensor. Inductive sensors find widespread applications in metal detection, position sensing, and proximity switching in various industrial settings.

- Capacitive Sensors: These sensors measure changes in capacitance caused by the presence or proximity of an object. They are widely used for level measurement in tanks and silos, position sensing in robotic systems, and proximity detection for automated processes.

- Ultrasonic Sensors: These sensors utilize high-frequency sound waves to measure distance, detect objects, and determine levels. They emit ultrasonic pulses and measure the time the sound waves reflect back from an object. Ultrasonic sensors are commonly used in applications such as obstacle avoidance in robotics, level measurement in tanks, and proximity sensing in automated guided vehicles (AGVs).

- Photoelectric Sensors: These sensors operate based on the photoelectric effect, where light striking a surface causes the emission of electrons. They are used for object detection, color sensing, and position sensing. Photoelectric sensors are widely employed in applications such as sorting and counting objects on conveyor belts, detecting the presence of objects in packaging lines, and controlling automated machinery.

- Infrared Sensors: These sensors detect infrared radiation emitted or reflected by objects. They are used for temperature measurement, motion detection, and flame detection. Infrared sensors find applications in various fields, including process control, building automation, security systems, and fire detection systems.

This categorization provides a general overview of the major types of non-contact sensors and their key applications in industrial settings. The choice of the most suitable sensor depends on the application’s specific requirements, such as the type of object to be detected, the desired measurement range, and the operating environment.

Applications of Non-Contact Sensors in Industry

Non-contact sensors find widespread applications across a multitude of industrial sectors. In manufacturing, they are crucial in automating production lines, ensuring product quality through precise measurements, guiding robotic systems with enhanced accuracy, and monitoring critical process parameters in real time.

Within process control, these sensors are invaluable for tasks such as measuring levels in tanks and silos, regulating fluid flow, monitoring temperature variations, and controlling pressure within systems. In logistics and material handling, non-contact sensors facilitate efficient object detection, sorting, and positioning while enabling robust inventory management systems.

The automotive industry heavily relies on non-contact sensors for critical functions such as engine control, advanced safety systems like collision avoidance, and convenient features such as parking assistance. In the food and beverage industry, these sensors ensure product quality and safety through rigorous inspection processes, enabling manufacturers to maintain high standards of hygiene and consistency.

Furthermore, non-contact sensors contribute significantly to advancements in various other sectors. In aerospace, they are essential for flight control systems and aircraft maintenance. In the energy sector, they play a vital role in monitoring and controlling power generation and distribution systems. They contribute to developing advanced medical imaging techniques and non-invasive diagnostic tools in healthcare.

This diverse range of applications underscores the critical role of non-contact sensors in driving innovation and improving efficiency across a wide spectrum of industries.

Advantages of Non-Contact Sensors

Non-contact sensors offer a compelling suite of advantages that contribute significantly to improved industrial operations. By eliminating the need for physical contact, these sensors inherently enhance safety by minimizing the risk of damage to the sensor itself and the measured object. This reduces wear and tear, leading to longer equipment lifespans and reduced maintenance requirements.

Furthermore, non-contact sensors excel in terms of efficiency. Their rapid response times and high accuracy enable faster and more precise measurements, streamlining production processes and minimizing downtime. The absence of moving parts significantly reduces the frequency and cost of maintenance, leading to substantial cost savings over time.

Non-contact sensors enhance product quality by enabling precise and consistent measurements. This translates to improved performance, increased reliability, and reduced defects, ultimately benefiting manufacturers and consumers.

Finally, the versatility of non-contact sensors is a key advantage. They are suitable for various applications and can operate effectively in diverse and challenging environments, from high-temperature industrial settings to harsh outdoor conditions. This adaptability makes them invaluable tools for addressing the unique needs of various industries.

In summary, non-contact sensors are essential in today’s industrial environment. Numerous benefits, such as increased safety, increased productivity, lower maintenance costs, and higher product quality, come from their capacity to measure and monitor processes without making physical touch.

Non-contact sensor technology is expected to make major strides in the future. Continuous gains in sensor miniaturization are driven by ongoing research and development, resulting in more compact, smaller, and easier-to-integrate devices. Furthermore, real-time data collection, analysis, and remote monitoring will be made easier by incorporating non-contact sensors with the Internet of Things (IoT). This will optimize industrial operations and enable predictive maintenance. These sensors’ capabilities will be further improved by using artificial intelligence (AI) and machine learning algorithms, allowing them to recognize anomalies, adjust to changing situations, and make wise decisions.

The ongoing development and advancement of non-contact sensor technologies will greatly influence the future of industrial automation. Industries may develop manufacturing, process control, and many other vital areas by adopting these innovations and reaching new production levels, efficiency, and innovation.